WHO IS IT FOR?

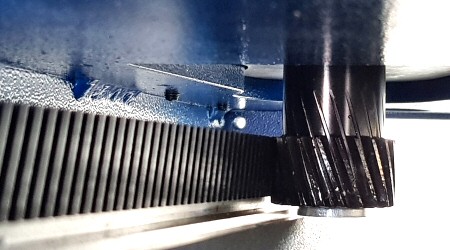

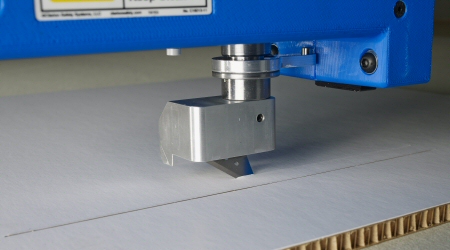

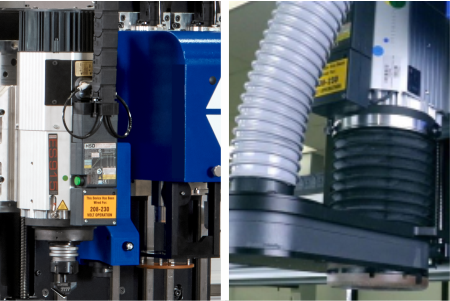

Trident is an innovative hybrid CNC production system combining heavy-duty routing with fast knife cutting for processing the broadest range of materials in all print finishing, signmaking, foam and graphics applications.

Popular applications include:

GRAPHICS AND PRINT FINISHING

Cut-to-print using multiple tools for all materials

POINT OF PURCHASE

Display stands, fixtures and fittings

ALUMINIUM COMPOSITE MATERIAL

Quick Tool Change spindle for high speed cutting and grooving of ACM and similar products.

SIGNMAKING

All types of 2D & 3D signs in woods, metals and plastics

FOAM PACKAGING

2D & 3D processing with router and knife tools

|

|